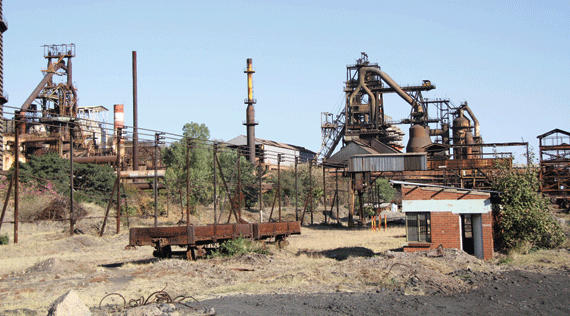

ZISCOSTEEL (now New Zimsteel) workers have turned to scavenging for coke residue at the company’s disused dump site to earn a living after going for more than two years without regular salaries.

The steel-making giant closed shop in 2008, leaving thousands of its workers without means of survival. Many of them now spend most of their time digging through mounds of coke residue left from the making of steel in the disused coke ovens.

A 50kg bag of coke breeze, which has finer grains compared to foundry coke, is sold for 60c ($12 per tonne) to a buyer who in turn sells the coke to companies who operate foundry plants at $240 per tonne.

Rosemary Tugwete said it takes her over five hours to collect 50kg of coke breeze. At best, she realises for $5 a week after toiling for more than 10 hours daily.

“We are being forced to work here because our husbands are not bringing any money at home and the only way left to earn a leaving is by scavenging,” she said.

Definite Shoko, an employee of Ziscosteel who said he received a $20 payout in December last year, said he now earns a living from the dump.

“I have to pay schools fees for my children and rentals which cost me a little over $200 a month,” he said.

“I cannot afford to pay for electricity anymore so I do without it,” Shoko said.

- Chamisa under fire over US$120K donation

- Mavhunga puts DeMbare into Chibuku quarterfinals

- Pension funds bet on Cabora Bassa oilfields

- Councils defy govt fire tender directive

Keep Reading

Others dig for foundry coke, which sells for a little more than coke breeze at $5 for a 50kg bag, to the middlemen, but is rare and normally involves dangerous work.

Workers say they have not been paid full salaries since 2011 except for a brief intervention by Essar in 2012 before the firm suspended paying salaries, citing lack of production.

The fall of Ziscosteel has also hit Redcliff Town Council hard.

The municipality’s finance committee chairperson, Clayton Masiyatsva, said owing to the collapse of the steelmaker, revenue inflows to the local authority had fallen by over 60% from the peak of Ziscoteel operations.

“Instead of collecting $300 000 a month we now collect somewhere in the region of $140 000 and for us to continue pushing people without any earnings to pay their bills is just difficult,” he said.

At the height of its operations, Ziscosteel was Africa’s largest integrated steel works and employed over 5 000 direct employees. It still has 3 500 workers on its books.

The African unit of India’s Essar Group in November 2011 agreed to buy 54% in the company in a deal worth $750 million, with the government keeping 36% and 10% to be owned by minority investors.

But its reopening has been held up by squabbles between the new partners over ownership of mineral claims, although government eventually agreed to transfer 80% of the rights to Essar while keeping the remainder.

Last month, Industry and Commerce minister Mike Bimha said the reopening of the company would take time because of the work involved in resuscitating its operations.

Essar will repair and refurbish key technology units such as the coke oven, the sinter plant, the steel-making plant, rolling mills and lime plant as well as install a new blast furnace while a new captive plant and oxygen plant would also be installed. — The Source