The declining capacity utilisation in Zimbabwe’s industry shocked a visiting team led by the Office of the President and Cabinet after it emerged that Lobels Biscuits and Sweets is running its Bulawayo factory on antiquated ovens commissioned in 1957.

BY BLESSED MHLANGA

The team, which also had diplomats and regional bankers, toured companies in Midlands and Bulawayo to assess their capacities and constraints.

Flour is still hand-fed, the production chain snails through the ovens, which consume high levels of electricity owing to old technology and low efficiency levels.

Human labour is still needed to pack the famous cookies and other products at the end of the production line pushing company overheads and the cost of production up, resulting in the uncompetitive pricing of finished products.

The story is no different with most manufacturers in Zimbabwe, whose companies rely on obsolete technology to fire up today’s industry.

National Blankets is still in the dark ages, still supplying knitted blankets whose major consumers are now prisons and hospitals.

- Chamisa under fire over US$120K donation

- Mavhunga puts DeMbare into Chibuku quarterfinals

- Pension funds bet on Cabora Bassa oilfields

- Councils defy govt fire tender directive

Keep Reading

This at a time the world has moved to woven blankets commonly referred to as “two in one”.

Even still, the use of machinery first employed in 1940 pushes the company out of business outside government protection through imposition of stiff taxes or the banning of the cheap imports into the country.

Lobels Biscuits and Sweets, managing director, Clinton Lecluse said if his company could acquire new machinery, production costs could be halved with prices becoming more competitive.

He, however, says this would take a long time because outside financing for retooling is expensive and at times unavailable.

“The political risks associated with Zimbabwe among other issues have made getting financing for retooling difficult to access.”

Currently Lobels is in the market looking to acquire a $2 million oven, but Lecluse said the exercise was a challenge due to the absence of financing.

“The proposal is solid, the only ingredient missing is financing. It is unaffordable at the current interest rates being offered in Zimbabwe. It will improve our production capacity and give us a major stroke to increase exports and cut our overheads,” he said.

Other companies reported that they are failing to fulfil their orders both on the local and international market owing to obsolete equipment. Leaford Electric Rewinds, a major manufacturer of electric transformers, is currently sitting on orders worth $80 000, which they are failing to meet owing to ineffective machinery.

The company, the sole supplier of 25 KVA electric transformers, uses machines which require manual labour to cut very hard sections of steel.

Technical director Orphan Bhiza said the time taken while using old machinery was not competitive for business in a modern industry, where cheap imports are now readily available.

His company needs $500 000 to ensure that they meet the entire needs of power utility, Zesa, which is forced to import most of its transformers. General Belting Holdings, a major supplier of conveyor belts, still use manual block chains to lift heavy weights.

To make matters worse, electric motors in use at the company are more than 20 years old and less efficient, but consume more power while pushing costs up.

Lobels Biscuits and Sweets still employees 550 people to mix flour then carry and pack biscuits and sweets on the packaging line, work done by machines in most industries around the world.

At Justin Clothing designing of clothing and cutting of fabric is still done by hand, while in other parts of the world this work has been computerised and mass produced, reducing the cost of products and pricing Zimbabwe out of the international market.

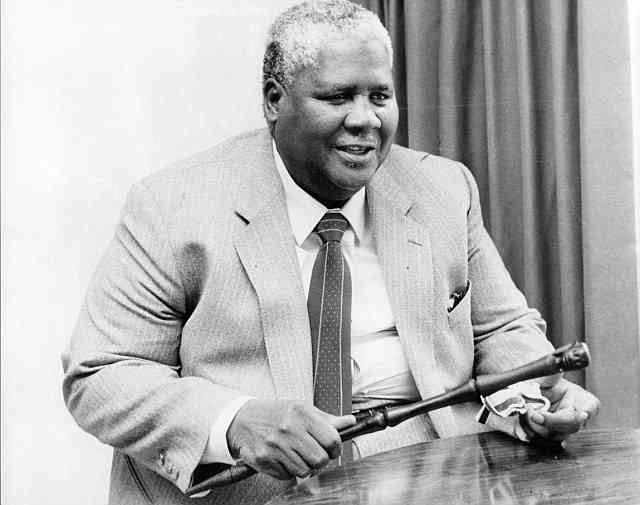

Confederation of Zimbabwe Industries (CZI) president, Busisa Moyo said most of his members were being weighed down by old machinery, saying the need to retool was critical for Zimbabwean industry.

He noted that after the economic collapse during the hyper-inflationary era, most companies were set back 15 years and had lost market share completely.

“The need to retool is there and most companies, who are members of CZI, were set back during the hyperinflationary era, but what is important for us is to get the market share back and after getting it we consider retooling. No industrialist would want to retool and then look for the market,” he said.

Moyo had no kind words for the finance sector, saying they had failed to come to the aid of industry because they were either slow or lacked innovation, forcing Zimbabwean companies to engage outside financiers.

“Local financiers offer facilities that are not attractive to industry especially for retooling because an 18 month loan at a cost of 35% is not ideal for capital projects such as buying machinery.

In fact these rates incentivise smuggling at our border posts,” he said.

He said in view of the state of machinery in Zimbabwean industry, CZI was moving to have suppliers of genuine machinery and equipment at next year’s Zimbabwe International Trade Fair, so that they assist old factories which are now re-emerging.

Moyo said CZI will also invite bankers at the premier trade fair, both locally and internationally, in an effort meant to bring lasting solution to the machinery crisis, which has hit the country.

The Africa Export-Import Bank said it was willing to provide funding after assessing the industry situation in Kwekwe, Gweru and Bulawayo.

Regional manager Southern Africa, Gift Simwaka said he was ready to offer a life-line worth $100 million to Zimbabwean companies at the correctly priced levels.

“It is a correct assessment that Zimbabwean industry is an industry without machinery, this is why we are prepared to offer ZETREF 2 [Zimbabwe Economic Trade Revival Facility], which will see us increase our offer from $50 million to $100 million and this money should be adequate to meet the company needs,” he said.

“If the company needs $5 million we give it just that and not $300 000.”